What can I say… preparation is crucial! No Im not kidding – weather it would be coating or gluing, 70% of the time it will be preparing the thingy into right mode.

What I have learned is:

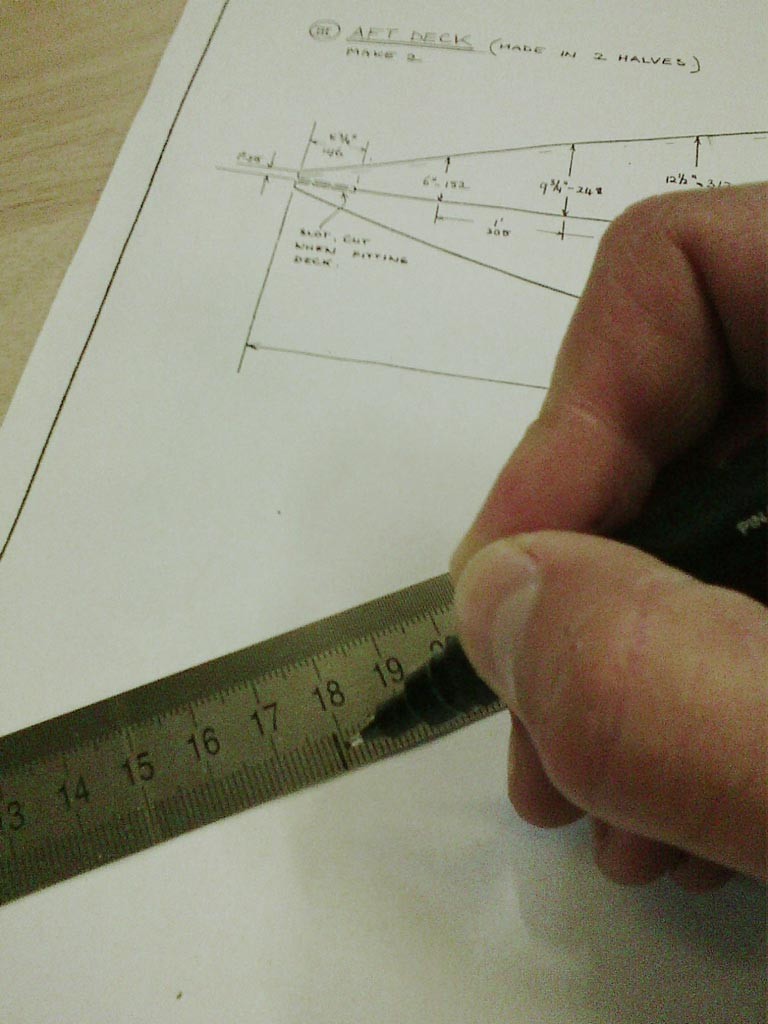

* take your time and check the measures or you learn it the hard way 😉

* check the coherence of the fittings: are you gluing this fine looking piece of hand crafted wood to a place where it really belongs?

* write everything down on the pieces: which piece of wood would like to mate with certain part of ply and which side down it prefers do to this!

* draw the lines – it makes hell of easier to lay down the glue

* prepare all the stuff you need for gluing/coating: brushes, spreaders, rollers – all clean and ready to go… not to mention nitrine gloves , rags for cleaning, mixing cups & sticks… its much easier to have those in hand rather than dig around in your work bench and litter everything with uncured epoxy, believe me :);

* and a clock! yes exactly, a whatch: this is for keeping an eye on time during mixing of resin and hardener. I went for 45 seconds per squirt of resin/hardener in normal conditions, usually a bit longer. It is really easy to loose sense of time, especially when you are mixing your tenth cup of epoxy of the day and it is rather tempting to have much shorter minutes counting in your inner biological clock…;

* last but not least: if you are inexperienced, do yourself a favor and deal with small patches in first place! After you have acquired some experience with epoxy then you may have start bragging around with the stuff :);