Read my face: three years in the garage and now…

PS! Arno, Ranno and Veiko – thanks for helping me with the mast trial 🙂

Read my face: three years in the garage and now…

PS! Arno, Ranno and Veiko – thanks for helping me with the mast trial 🙂

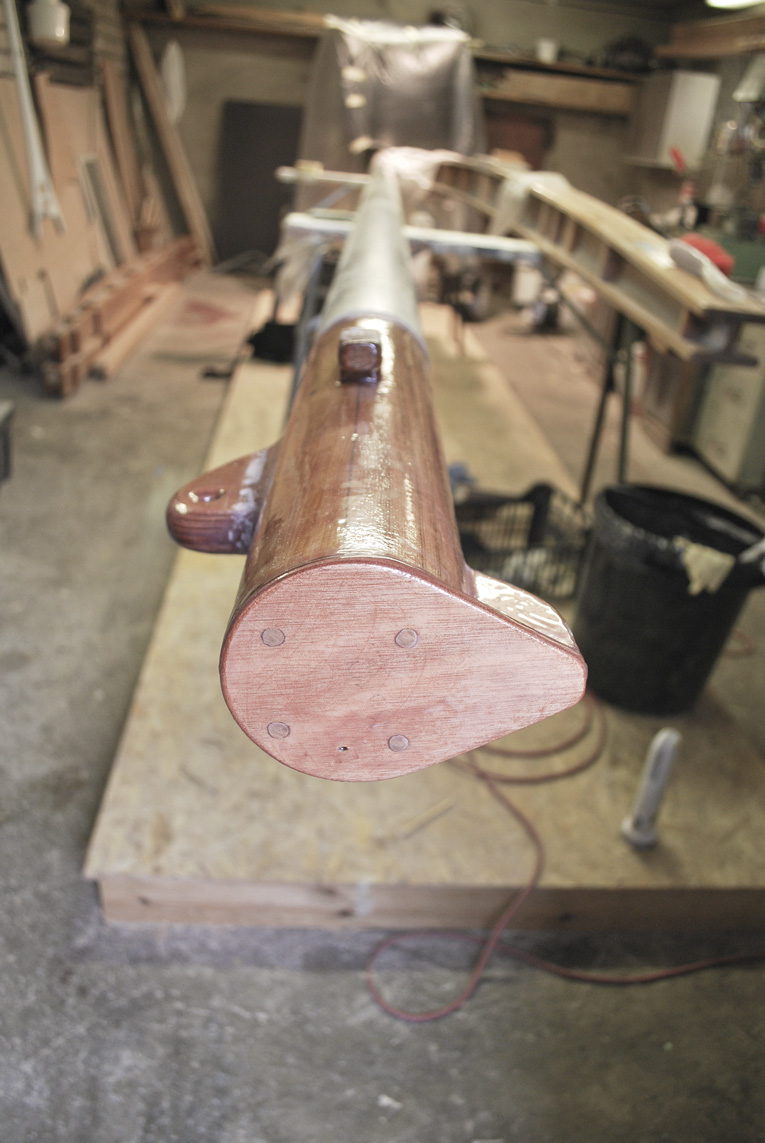

After couple of laborious days of planing-sanding-planing-sanding-swearing-sanding-planing-sweating-sanding-swearing-planing-sanding i finally managed to produce snugly fitting top and heel for the mast:

Its already August – soon enough nasty long, damp & dark winter will knock on the door… Still I have some glimpse of hope, as I finished port hull paint job — I only need to fit windows, main hatch hinges and rudders.

Port hull with fresh paintjob

Just look at these neat curves 🙂

Just some few odd jobs left… here’s centre beam under pressure waiting epoxy to reach its final stage (slow hardener for gluing; 50% fast, 50% slow for fillets)

Starboard hull with its new paint (same as port hull — Tikkurila Temadur 20)

Playing with the paint & sniffing the fumes….

… two part epoxy based Tikkurila Temacoat RM40 serves as primer for the hull, I will let it to set for a few days, then there will be applied two part polyurethane Tikkurila Temadur 20 fas a topcoat. Interiors are already coated with several layers of Temacoat, which is a bit easier to apply in constrict spaces, as it do not go off too quickly after mixing and its a bit more viscose as well, a true virtue considering the situation where painter has to squeeze himself into the rear section of cabin, size of a smaller nightstand, armed with pot of potent smelling paint, flashlight, small brush and watering eyes.

… a fancy DIY knob for main hatch locking system, made of 2 layers 6mm plywood (will see how it works…)

… and little bit of woodwork as well — a base for jib block, made from 2 pieces of oak, clued and screwed onto the hull.

I decided to abandon jib traveler and went for barber haulers.

Now I need one dry and warm day for painting the topsides and another for hull sides…

Port hull almost done, still lots to do…

… waiting in the list:

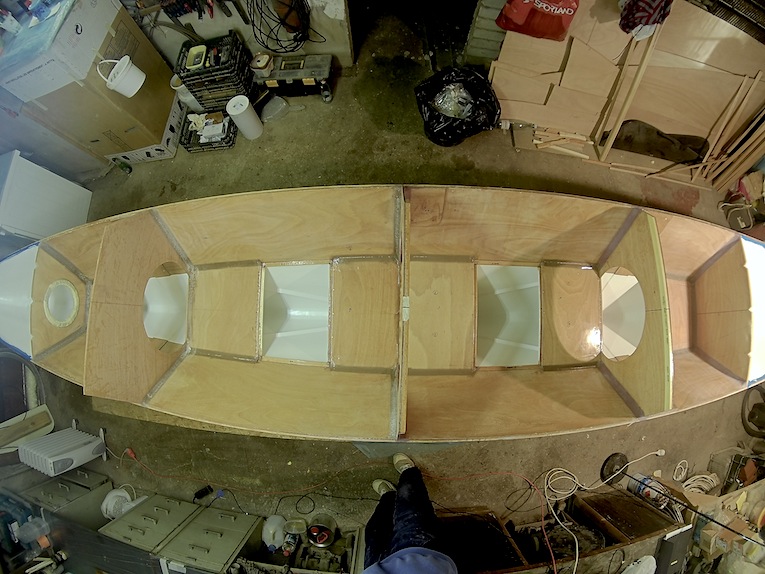

Bunks are ready for port hull. Now there will be some paint job (Tikkurila Temacoat RM40) and stringer job before gluing the decks on. Looking good, hopefully I could keep up the pace…

A fellow amateur Tiki builder Brad shared his experience in Southwinds magazine. Check out his story in page 44.

So… second hull got stitched up and yesterday I made some nice fillets for keel & bulkheads for 2 sections… I think its time to talk about little variations and changes I have made and plan to make into workflow, just to make whole process a little bit smoother and less time consuming.

Those modifications seem rather irrelevant, but again, when most of the (epoxy related) works are carried on by single person, then every little nuance start to play important role, especially those that help to reach results easier and faster.

Port hull, all stitched up, with glued sheer stringers and additional bunk bearers.

A key for levelling the hull.

Few weeks ago I bought from Mass last pieces of Douglas-Fir needed to complete hulls. It means two 5,45m 105x52mm logs.

Im still missing pieces for the crossbeams: they need to be 3,81m long with cross section of 120x20mm. I have to hope a miracle on that!

Anyway, I had to use again lots of Veiko’s elbow grease to cut them in suitable battens and planks.

Thanks again Veiko and Jaanika! Your help is again appreciated a lot!