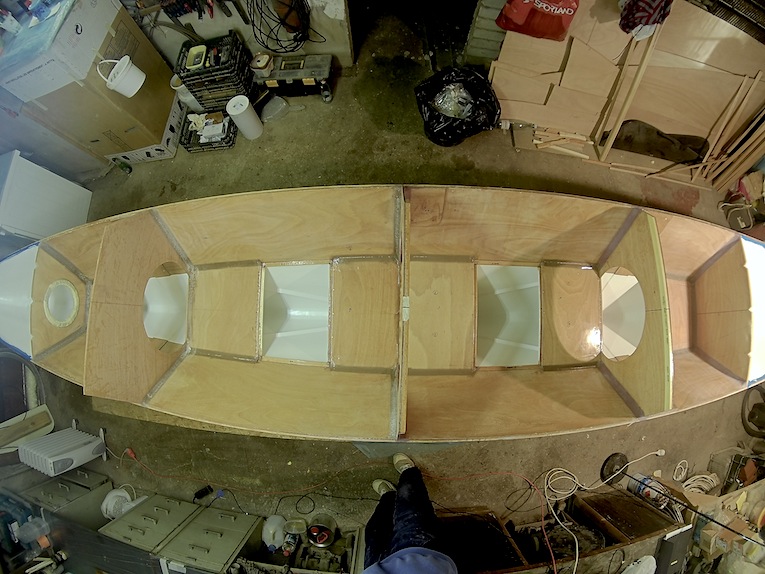

Port hull almost done, still lots to do…

… waiting in the list:

glass 2 cabin sides, glass tape main companionway & forward hatch coamingsglue beam sockets/padsbolt & glue beam/shroud lashing padsproduce forward and center beamproduce mast top and step for aluminum tubemake tillers & gaff- lash rudders to hulls (port hull needs lashing holes as well)

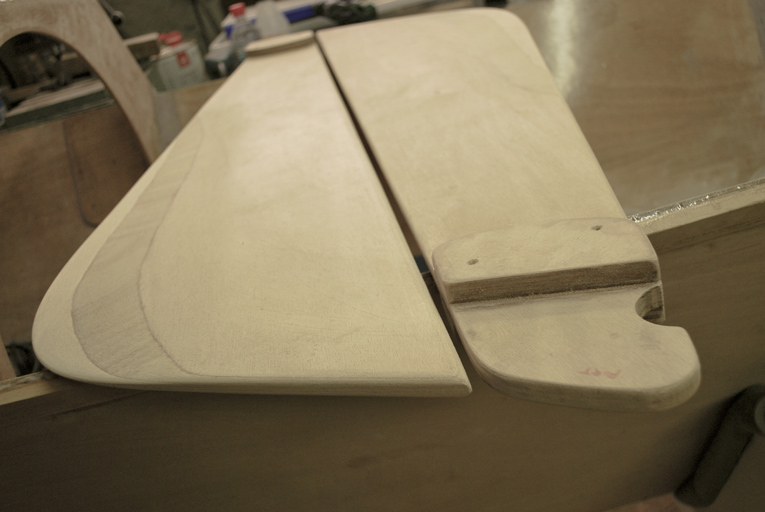

- fabricate slatted deck

produce forward & main hatch for port hull- install all the necessary small bits that will make run everything smoothly (supporting pads for deck, jib blocks and barber hauler, main hatch locking system, beam cleats etc)

sand & paint everything (including starboard hull)install port hull windows- raise mast & get out onto water