Read my face: three years in the garage and now…

PS! Arno, Ranno and Veiko – thanks for helping me with the mast trial 🙂

Read my face: three years in the garage and now…

PS! Arno, Ranno and Veiko – thanks for helping me with the mast trial 🙂

Its already August – soon enough nasty long, damp & dark winter will knock on the door… Still I have some glimpse of hope, as I finished port hull paint job — I only need to fit windows, main hatch hinges and rudders.

Port hull with fresh paintjob

Just look at these neat curves 🙂

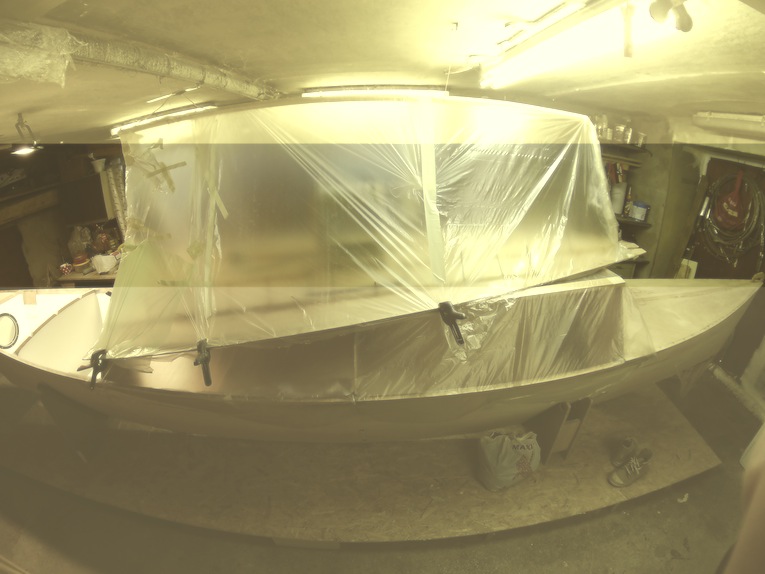

Just some few odd jobs left… here’s centre beam under pressure waiting epoxy to reach its final stage (slow hardener for gluing; 50% fast, 50% slow for fillets)

Starboard hull with its new paint (same as port hull — Tikkurila Temadur 20)

Port hull almost done, still lots to do…

… waiting in the list:

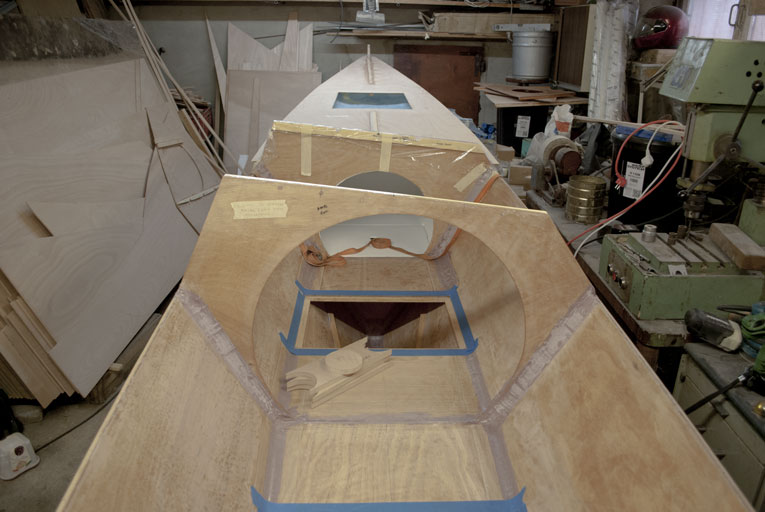

With extra pairs of helping hands it was rather pleasing act to glue on the forward deck.

Thanks a lot, mates!

Those freshly glued front deck stringers got nice and cozy overnight stay under this i-love-to-hassle-with-masking-tape tent

So… second hull got stitched up and yesterday I made some nice fillets for keel & bulkheads for 2 sections… I think its time to talk about little variations and changes I have made and plan to make into workflow, just to make whole process a little bit smoother and less time consuming.

Those modifications seem rather irrelevant, but again, when most of the (epoxy related) works are carried on by single person, then every little nuance start to play important role, especially those that help to reach results easier and faster.

Port hull, all stitched up, with glued sheer stringers and additional bunk bearers.

A key for levelling the hull.

shot by mr Gab

So, hull sides got finally glassed, therefore I decided to reward myself with little rudder play.

Here is shot from trial fitting of rudder lashings.

I like those simple & genius rudder fittings… There is some kind of primal pleasure in splicing rudder to the stern… and not paying some extra silver for expensive rostfrei attachments….

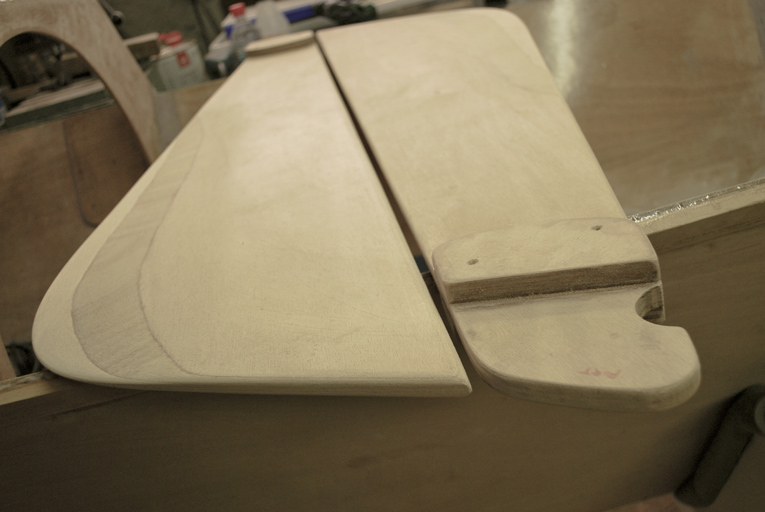

So before stinging cold from Russia struck… I managed to glue fore deck as well. Aft deck was done already in November.

Now both of them are glued, trimmed back and rounded, ready for next phase.

During nighttime it drops down to -20 Celsius outside and it takes too much effort to heat garage sufficiently for epoxy work, so I spend some therapeutic hours shaping and smoothing rudder blades. Hopefully there will be soon some nice warm lows dispatched from North Atlantic so I could resume to gluing work, which means attaching the cabin sides and top, small round fillets for deck stringers, fillets for holes left by temporary screws I used occasionally during deck works.

So whats the balance for now… With a bit more than half a year I have managed to assemble starboard hull up to the decks. Later ones have been prepared for gluing.

Next item in the plan is to paint undersides of the bunks before starting with cabin sides. All nicely prepared, waiting for the right vibes…

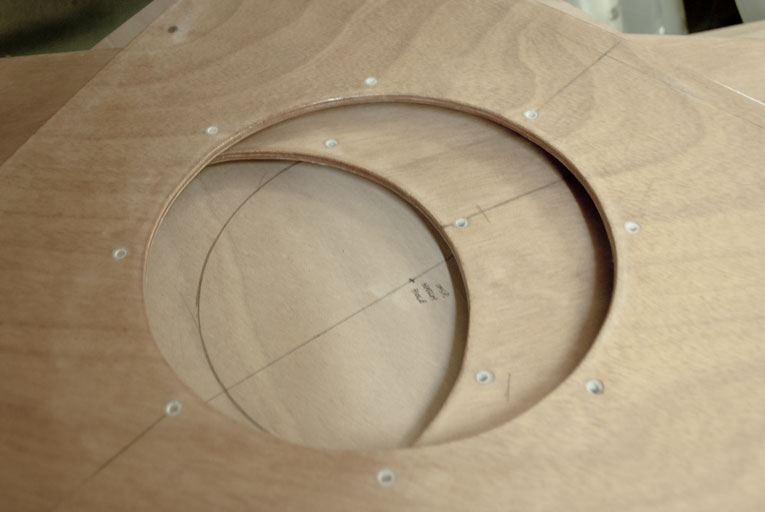

Broadsides & bulkheads of the port hull were cut out already in summer. So for a change of scenery I started with gluing deck-beams and bunk bearers, also I prepared nice thickened-epoxy holes for taking inspection hatch bolts. Maybe its overkill… on starboard bulkheads I used just screws.

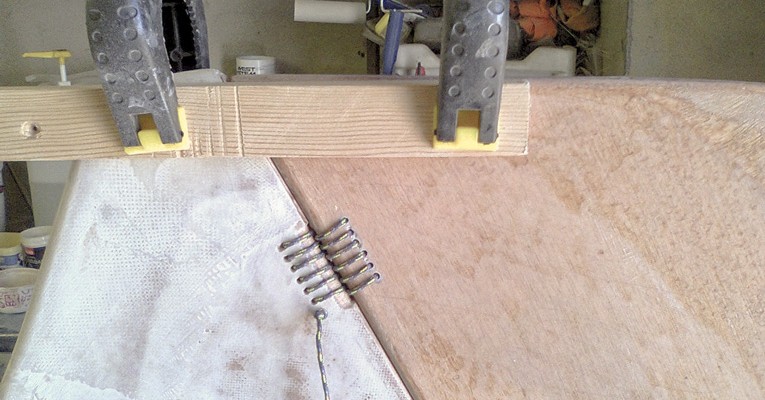

Last week I spend some therapeutic hours and cut out small pieces from the 15mm ply, namely lashing pads and butt blocks for beams…

… then continued with beam web pairs, which also ended previous sanative session with a cruel fact that I miss few inches of ply sheet in order to complete all three pairs. Apparently when I produced rudders, stem & stern posts in spring, I went for too excessive safety margins…

Bugger!

Meanwhile I have prepared decks for gluing, this means attaching the stingers, epoxy coating and painting undersides. Loathed paintjob… This Tikkurila Temadur is indeed a quite nasty stuff working in under-ventilated garage I have there, but since it sticks into epoxy pretty well I guess I have to be pleased with it, no intention to get lost in the poly-carbonates maze again…This time I made my life a bit easier and bought proper thinner as well, which means I do not have to worry about short pot life anymore and also I can avoid slight coagulating problems I had previously when I was working too slow.

Anyway what I have recognized is that I have hit the 400 hour benchmark already, since I have worked at least 16 hours per week during summer months and at least 8 hours per week during spring & autumn. By no means I would like to contest Wharram estimates, Im pretty convinced that one could relay Tiki 21 within 400 hour time frame whether he is highly skilled or just a novice bloke who is desperately in rush to get onto the water soon as possible.

In my case… well I haven’t been a prompt starter all of my life. I need to develop a kind of feel of the process, tools and materials, only when I’m certain that those fresh spread wings will carry I would dear to dive head fist into the matter. Otherwise there is high probability that I will mess something up completely.

I had to castrate my inner perfectionist pretty much in the start anyway.

But furthermore I’m still struggling to fully disclose this little universe boiling there down in the garage. I guess its rarely not just a boat building for numerous amateur comrades out there. Building a 21 foot catamaran isn’t just a pastime endeavor for most us novices, Im pretty sure.

It just means just too many countless hours of researching, watching YouTube wow-to videos, fearing, hoping, being paranoid over the measurements, recollecting, digging out rare materials, spending money to gadgets you cannot do without, buckling down eternity on your knees with jigsaw, spending agonizing hours in folded position like a maniac flamingo, trying to spread fillets, then sanding fillets, after which reshaping fillets again because you messed up little bit in first time, and then again you are sanding those fillets and then back again behind your computer trying to make sense of all those controversial advice, opinions, dogmas, principles and tricks served in forums, DIY videos and blogs. Your knees hurt, your legs let you down, those dozens of tiny muscles you haven’t been aware of so far, those hurt as well, your nostrils are clogged, as well your brain, it has gone off due a short circuit, that’s because constantly you had to use both hemispheres simultaneously.

So whats the point of all? Its not easy to find a straightforward answer to this, I guess its just constellation of many small, often invisible things, thin threads spinning into taut line which may make up your safety rope in the end. All you have to to is just grab it and see where it pulls, or from where it pulls you out…

Gluing bunks. Deviated from the building instructions a bit – I did not stitch the bunks, instead I went for temporary screws and some nice bricks. Also I did not loft the curvatures like Wharram suggest, therefore I took the measures in situ and cut out the bunks accordingly with strait edges against the broadsides. The camber of the broadsides leaves just a few millimeter wide gap between bunk and side, which would be easy enough to fill with thickened epoxy.

Fillets. After colloidal silica and epoxy mix has been cured next step was sculpting some nice radiuses (low density filler) for upper- and underside of the bunks. Later one made me wish I was born as a bat – a job not suitable for sweating out the hangover 😉

I waited until upper side radius was almost cured, then laid gently 100mm 175g glass tape, smoothing with light strokes of brush until it was leaning tight against surface after which epoxy was brushed over.

PS! Peanut butter. If its not necessary to squeeze fillet into some narrow gap then peanut butter consistency would work best. It paid off to spend an extra minute to measure out the right consistency. At least for me.

I executed my first experiment with epoxy. Its my miniTiki above.

I decided to use West System, which is not cheapest, but its manufacture line seems most coherent and of course because it is very well known and proven brand in wood-epoxy boat building world. For an amateur like me it makes lots of sense to acquire all the epoxy, hardener, fillers, glass and other various bits and pieces from one manufacturer. I found that application information (including video tutorials) was most easily to be found for West System products. Not to mention that here in Estonia there are not much of other brands in retail.

I got my stuff from Bang & Bonsomer Estonia, although they seem to deal mostly with big guys, they were most helpful and I got all the components needed to produce desired epoxy magic.